INNOVATION

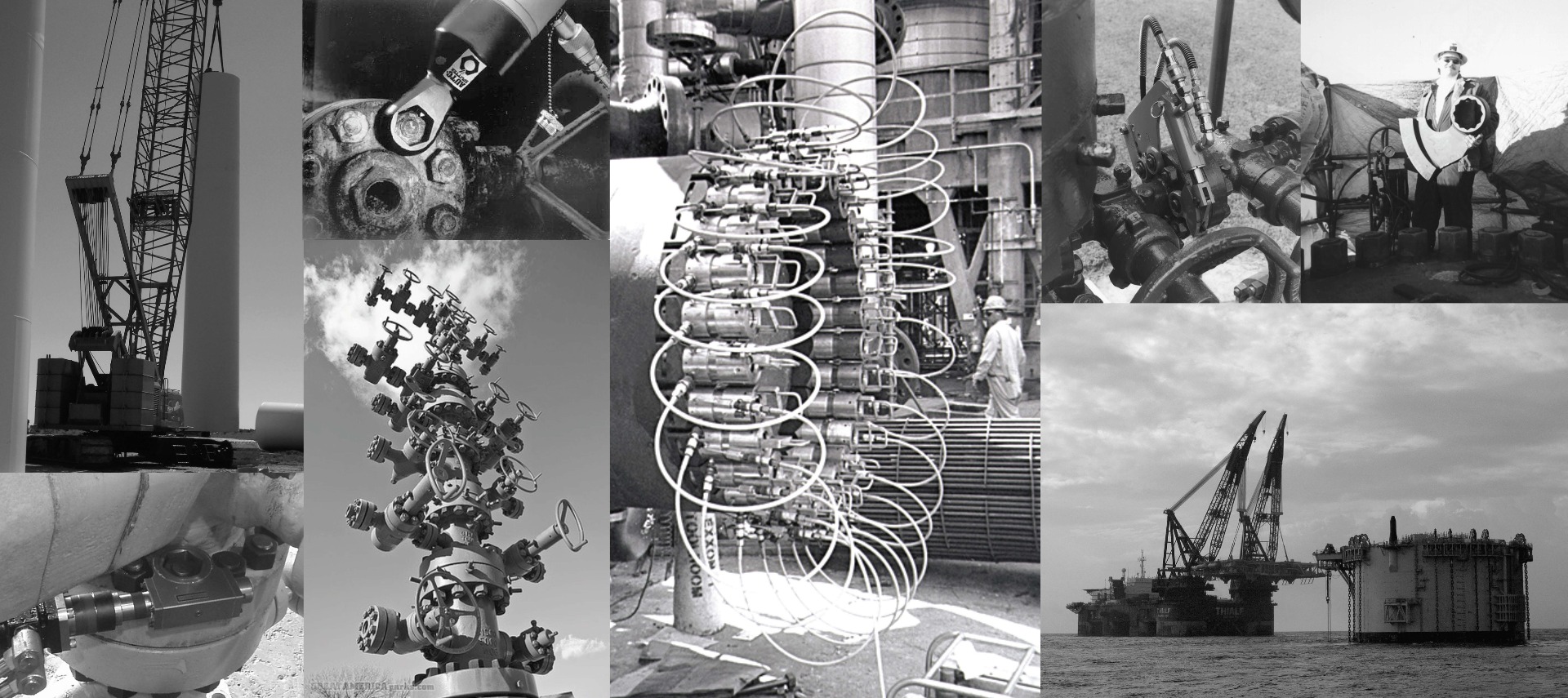

In envisioning the future of bolting technology, innovation becomes imperative. That’s why we’re dedicated to crafting ingenious solutions.

One such breakthrough is our ZipNuts™ - fully automated bolt-type systems designed for subsea deployment with ROVs, enabling tasks beyond manual capabilities.

Every day, we’re driven by the challenge of devising reliable solutions to meet the diverse needs of our customers.

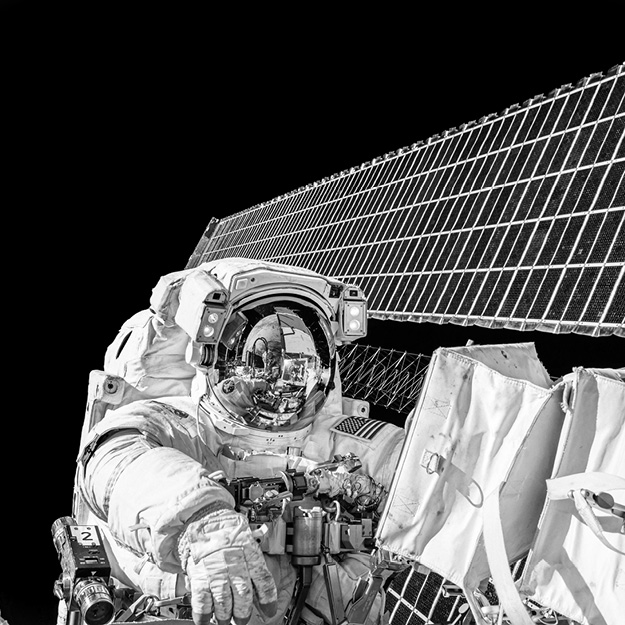

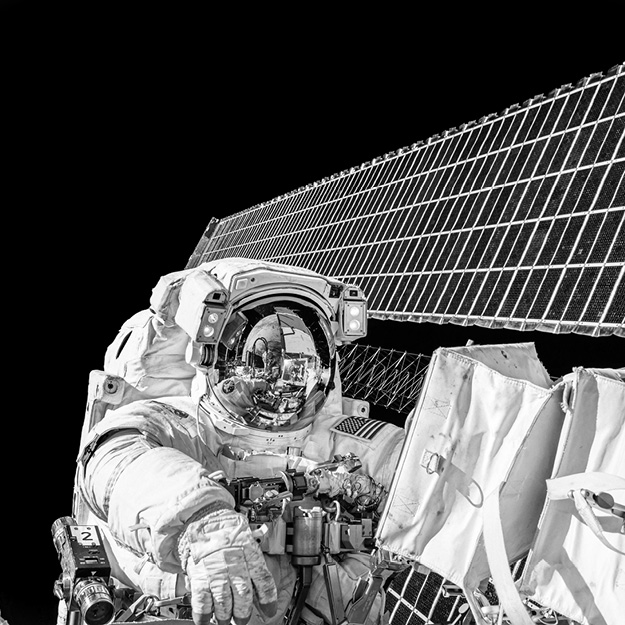

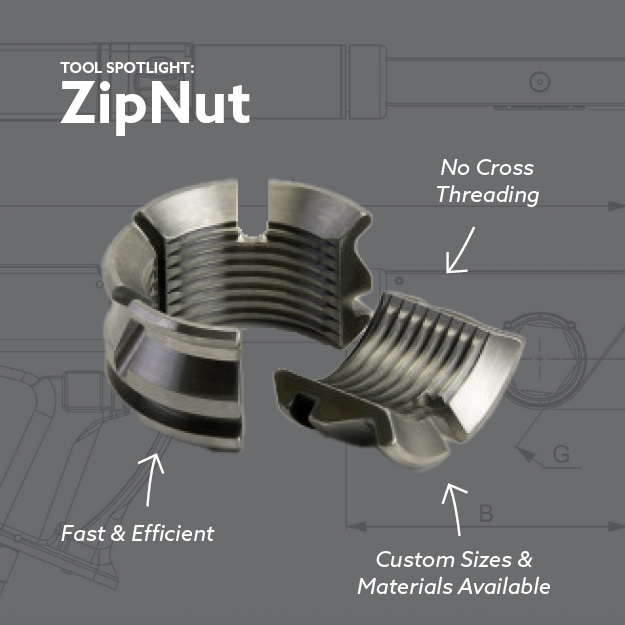

Looking for an out of this world solution to your bolt tension problems? Look no further than FASTORQ’s revolutionary ZipNut® Technology.

First developed for NASA for use on the Space Shuttle, International Space Station and Hubble Telescope, ZipNuts are designed to eliminate the time-consuming motion of threading a traditional nut on a bolt in applications where speed, accuracy and reliability are vital.

FASTORQ’s ZipNut is quickly installed by simply pushing it onto a bolt in one motion. When it reaches the end of the bolt, it is tightened by a simple twist. That’s it. It’s locked in place.

ZipNuts also come in a Double ZipNut option that slides onto the nut in the same manner as the original, but give users the option to also remove the nut the same way with one quick turn and slide off the bolt. It doesn’t get much easier than that!

Not only is ZipNut Technology quick, it conquers many common bolt problems such as rust, paint and damaged threads.

ZipNut Technology works like this: A ZipNut can be installed by simply pushing in onto a bolt in one motion, eliminating the difficulty of threading a traditional nut. When the ZipNut reaches the end of the bolt's threads, it can then be tightened by simply twisting it.

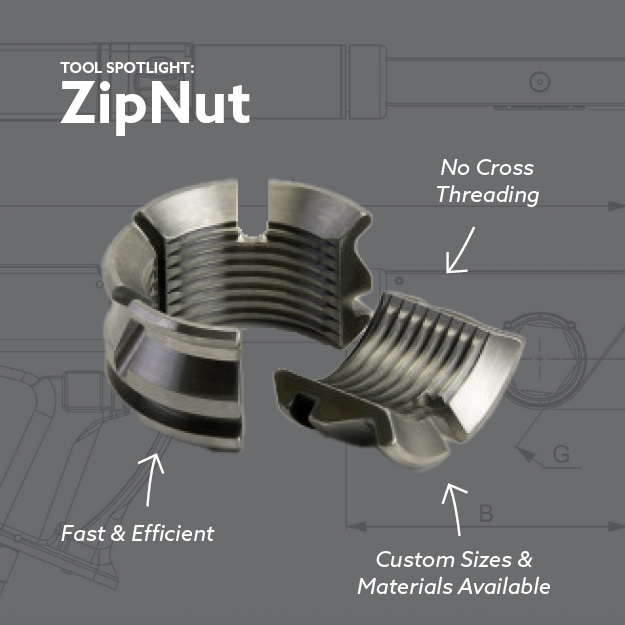

ZipNut at a Glance

• Replaces heavy hex nuts with a revolutionary simple, fast and reliable alternative

• Push on threaded nut

• Eliminates tedious, repetitious turning and cross threading

• Measures on wrench size larger across the flats than standard heavy hex nuts

• Fits standard bolts

• Available in different sizes and materials

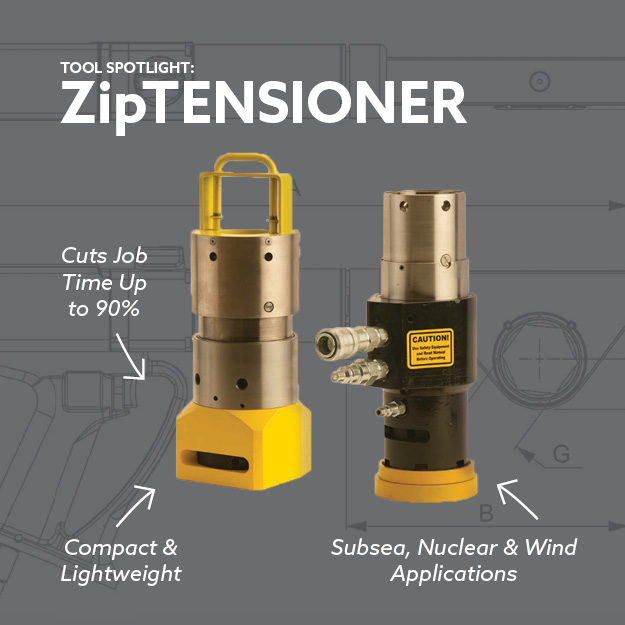

ZipTENSIONER is the ultimate in reliability and speed for bolt loading applications. The one-piece design provides 100-percent coverage on the same side of the flange and simultaneous tension of multiple fasteners.

ZipTENSIONER at a Glance

• Simultaneously tensions multiple threaded fasteners in half the time requred by conventional stud tensioners (eliminates manual rotation)

• Designs allows for 100% stud coverage from one side of any ANSI or API flange

• One piece installation: compact and light weight

• Low-friction seals are self-lubricating and provide unlimited shelf life

• Especially suited for wind turbine, subsea and nuclear applications

• Available in fixed and variable styles

By using Double Zip Technology, the ZipLIFT load connector and crane grapple provides safe and reliable industrial strength lifting in hazardous work areas.

ZipLIFT at a Glance

• Robotically retrieves and deploys heavy loads, either subsea or topside

• Models available with lifting capacities ranging from 35,000-600,000 lbs

• Hydraulic or pneumatic cylinders can be integrated into the system to release the thread segments

• Will not release until load is set down

• Shackles and pins are eliminated

• Especially suited for subsea and nuclear applications where human intervention is restricted

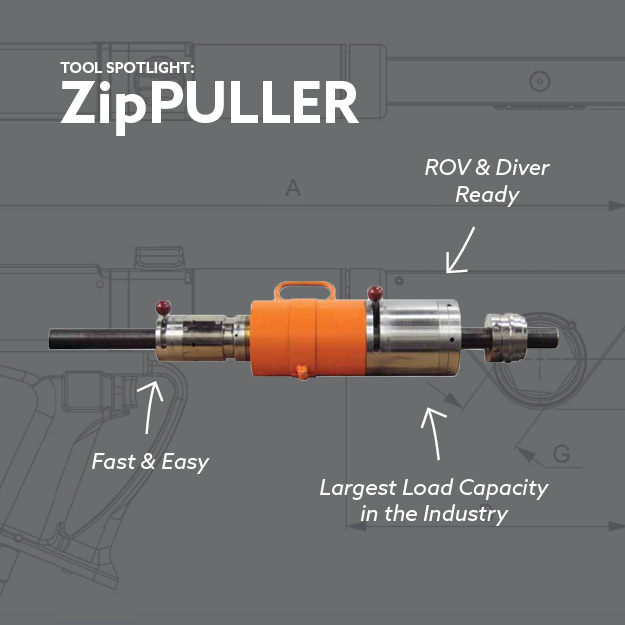

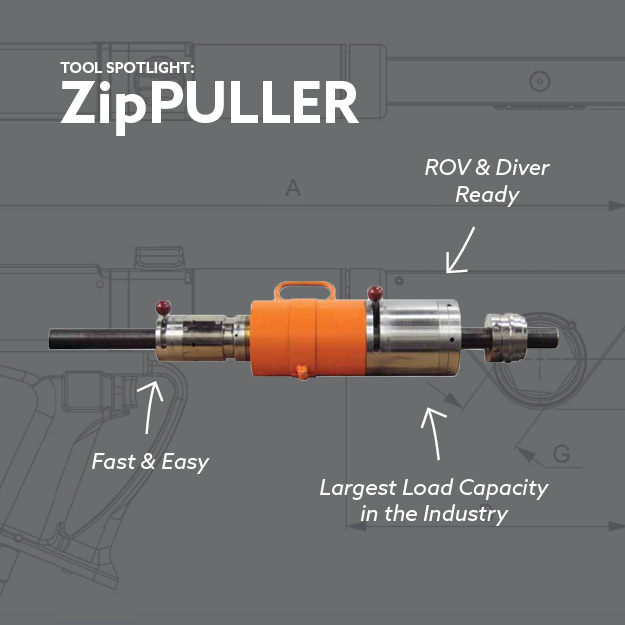

Ideal for challenging subsea flange connections and alignment or heavy equipment positioning and maneuvering, the ZipPULLER flange puller has the largest load capacity pulling system on the market. Its versatile and compact design works great with ROVs, hard suits and divers.

ZipPULLER at a Glance

• The fast and easy way to pull, align or mate flanges on land or underwater at any depth

• Largest load capacity pulling system in the industry

• ZipNut holds the load as the cylinder retracts

• Quick release levers open and close puller bars for fast installation and removal

• Hydraulic powered, 10,000 psi working pressure

• Versatile: ROV's, hard suits or divers can operate the system at any depth

• Easy to use: assembly pushes on and pulls off standard threaded rods

• Designed to use in multiple units with a single pump to provide uniform flange makeup

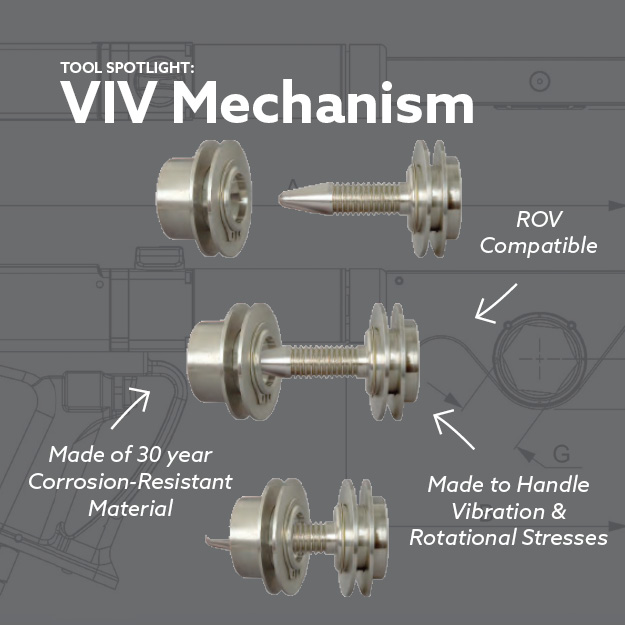

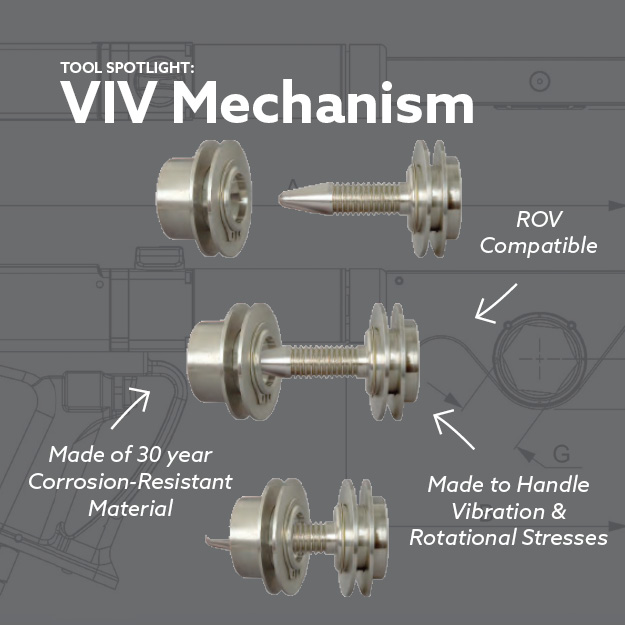

Vortex Induced Vibration (VIV) occurs when ocean currents flow past the risers that transport well fluids from the sea bottom to the surface/offshore production structures. VIV is extremely destructive to risers and associated equipment. The revolutionary design of the AutoZIP VIV Fastening Mechanism follows the same principle of a check valve but incorporates a female fastener with segmented threads which separate slightly to allow entry and engagement of the male fastener as it is pushed into the female segment. No rotation is required!

AutoZIP VIV Mechanism at a Glance

• Compatible with ROV tooling capabilities

• Rugged enough to withstand vibration and rotational stresses

• Made of material that is corrosion-resistant for 30 years